Smart Grocery Store Technology for Every Aisle, Every Department

All-in-one grocery technology for performance and compliance. Jolt equips groceries with powerful tools for labeling, task management, temperature monitoring, and team operations. Experience the future of grocery management.

Technology Built for Grocery Stores

Jolt gives grocery stores real-time visibility and data needed to transform their operations. We offer labeling, digital checklists, temperature monitoring, and more. Designed to assist with food safety compliance and consistent execution across all departments.

Jolt replaces manual processes with a technology-driven solution. We automate critical operations, ensuring accuracy, efficiency, and compliance from the stockroom to the shelf.

Jolt replaces manual processes with a technology-driven solution. We automate critical operations, ensuring accuracy, efficiency, and compliance from the stockroom to the shelf.

Labeling

Quickly create and print accurate labels reducing errors and improving compliance.

Lists

Create, assign, and track with ease. Make sure tasks are completed consistently and on time.

Sensors

Monitor critical temperatures in real-time, receive alerts for deviations, and ensure food safety.

Work Orders

Report maintenance issues, assign it to the right person, and track progress along the way.

Info Library

Cut down training time by integrating SOP tutorials with Jolts checklists in one central hub.

Temperature Probes

Automate the record keeping portion of cooling and holding logs to make compliance simple.

Scheduling

Track labor costs based on overtime and breaks. Employees can see and request trades on their own personal devices.

Time Clock

Equipped with face-detection and photo capture to ensure accountability and eliminate buddy punching.

Communication

Easily share information to employees. Receive confirmation the message was received and understood.

What do Operational Bottlenecks Cost You?

Running a grocery store means paying close attention to food safety regulations, and other daily tasks to minimize waste, maximize profits, and provide a good customer experience.

Do any of these sound familiar?

- Labeling Nightmares: Frequent printer jams, label drift, and misprints. This leads to to wasted material, wrong pricing, nutrition facts, and barcodes.

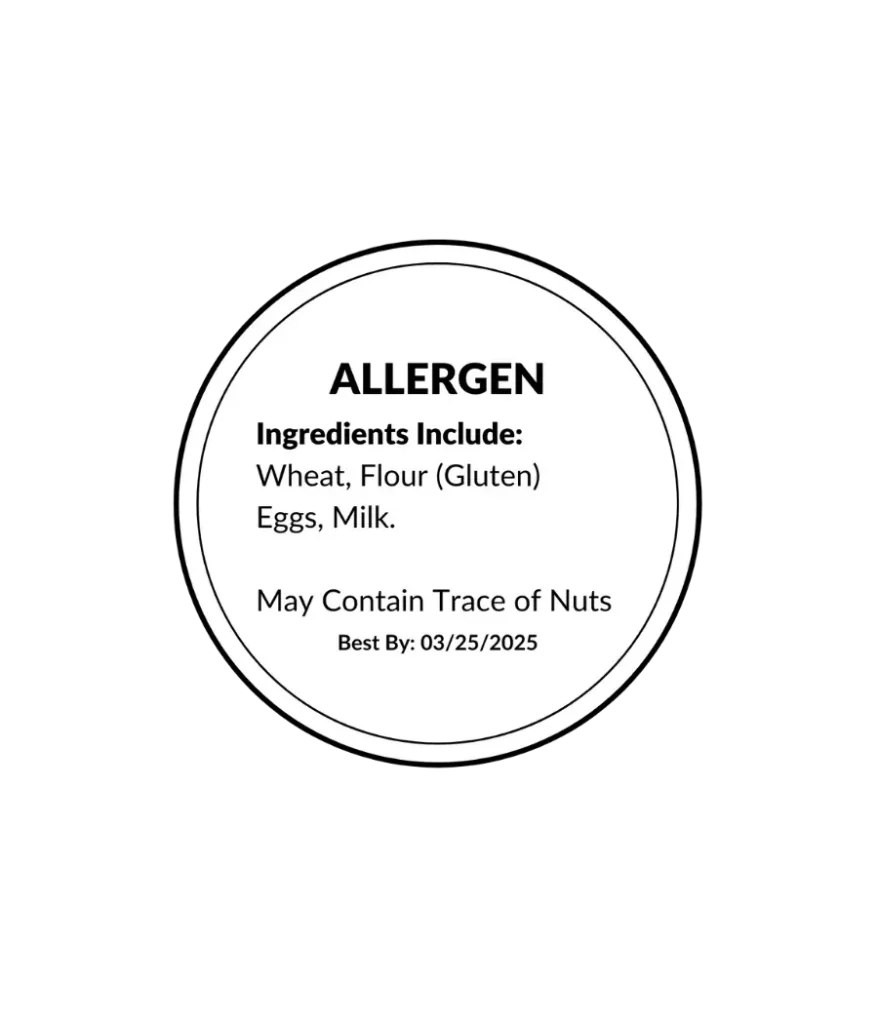

- Compliance Risks: Critical tasks left unfinished. Fridge temperatures fluctuating above safe ranges. Or labels that don’t display critical info like EBT or Dietitian’s Choice.

- Manual Burden: Labor hours spent updating label information for multiple locations. Temperature monitoring is done manually every few hours rather than being automated.

These aren’t just inconveniences; they impact revenue, compliance standing, and customer trust.

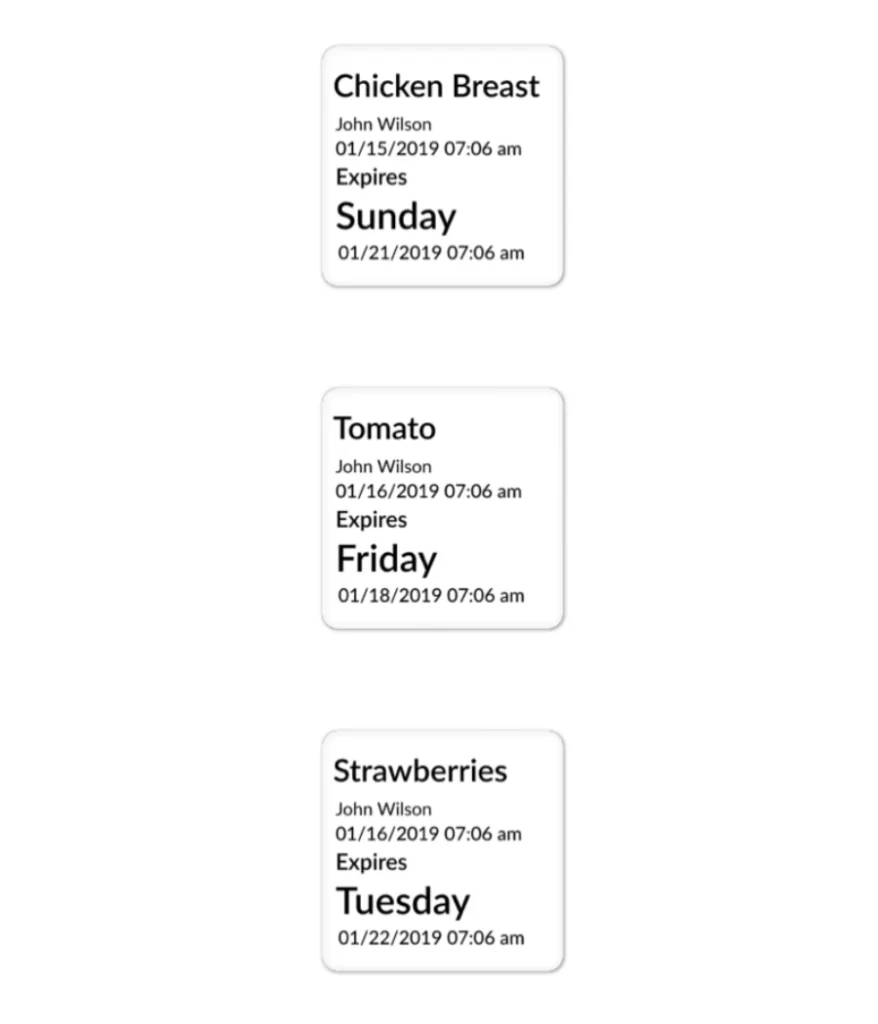

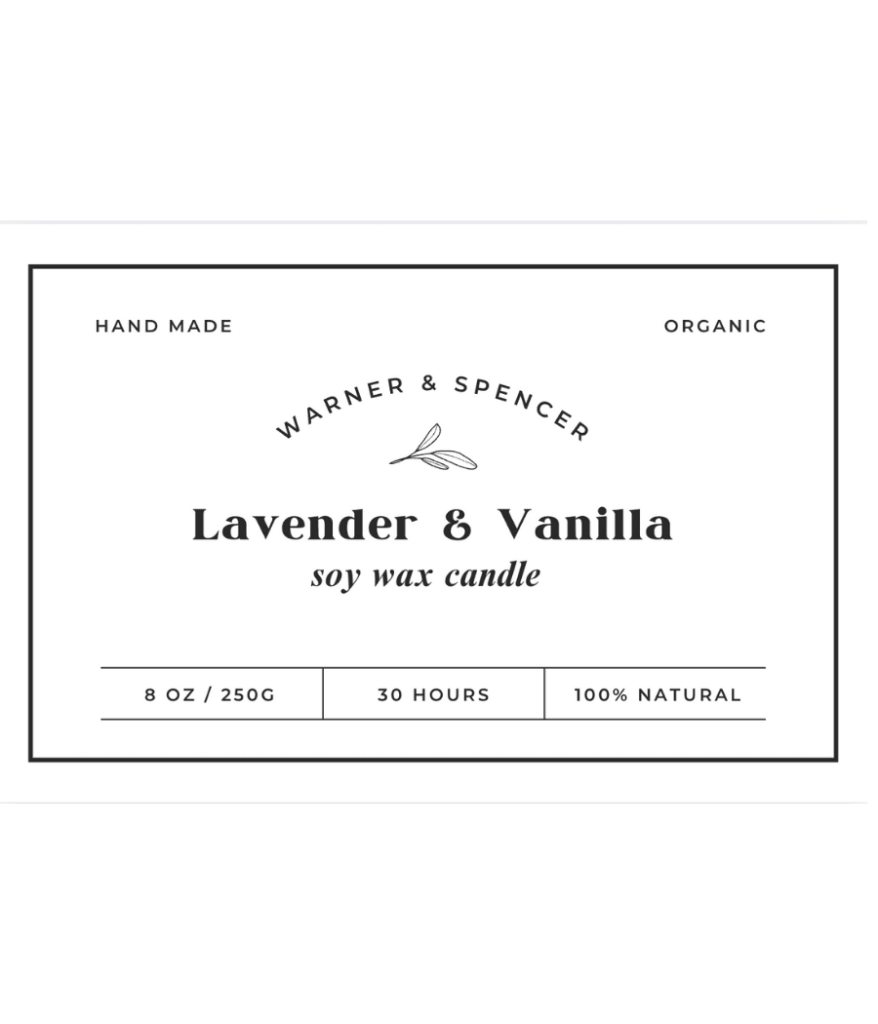

Jolt’s Grocery Store Labeling System

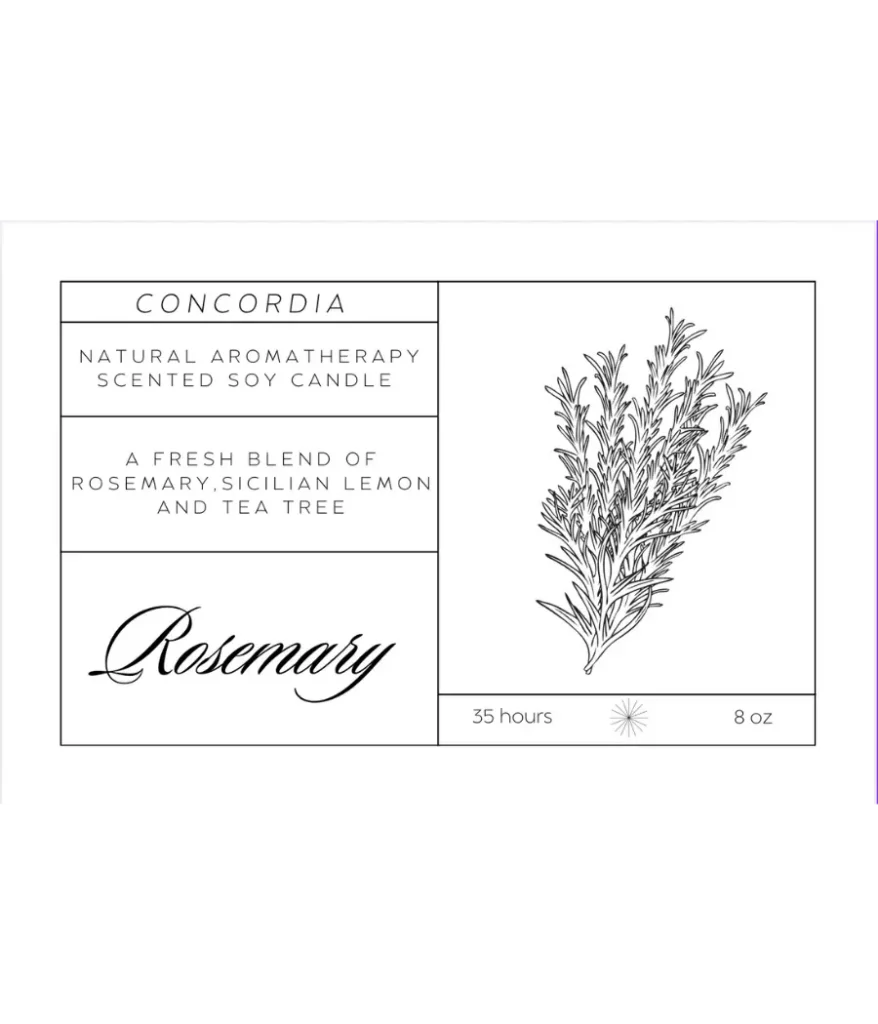

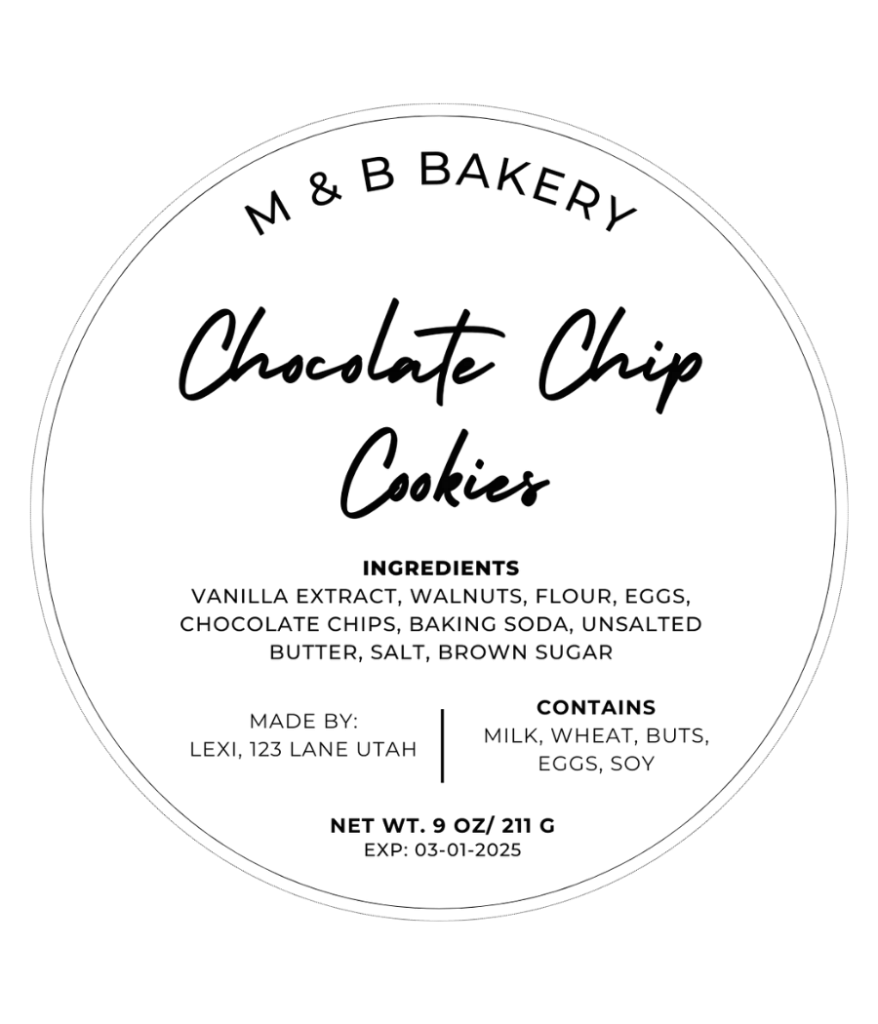

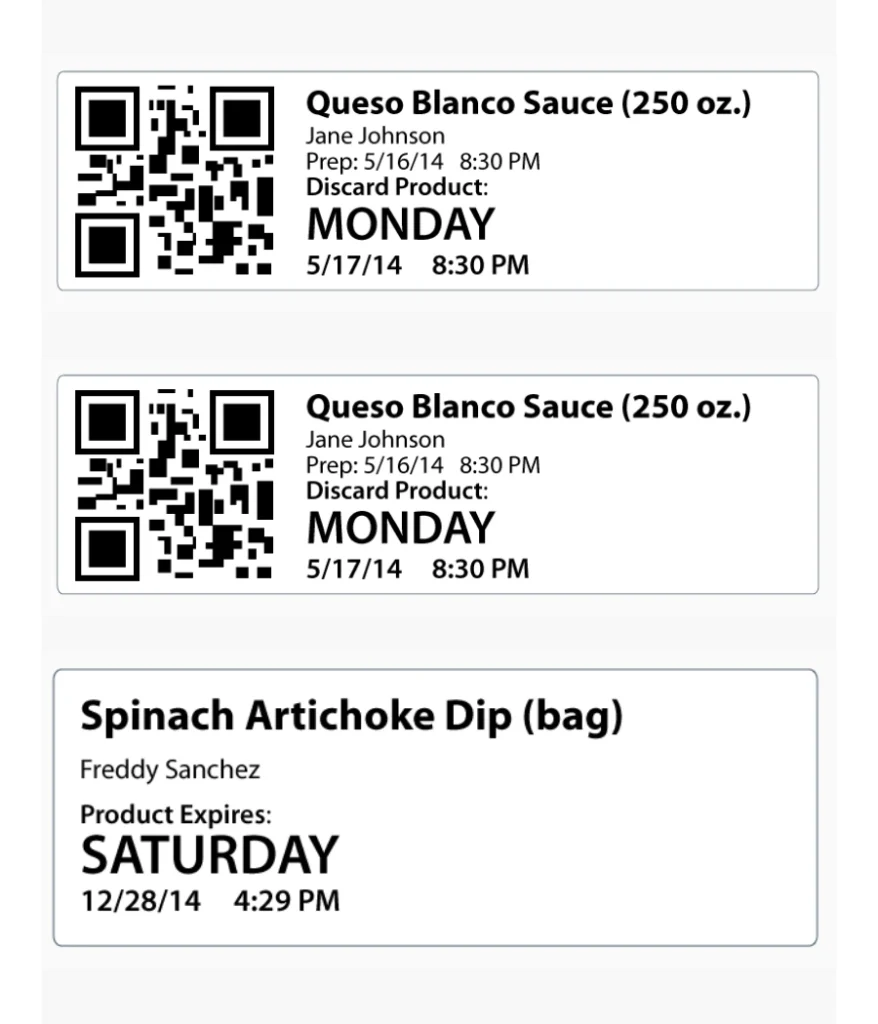

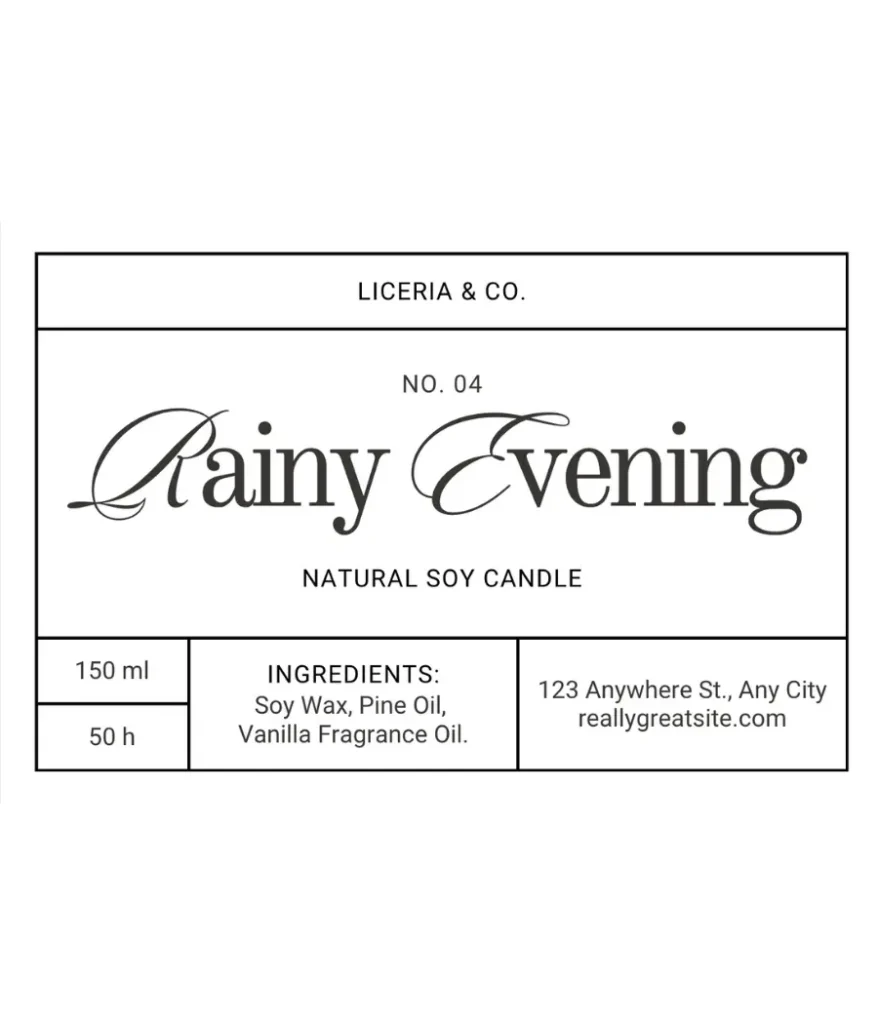

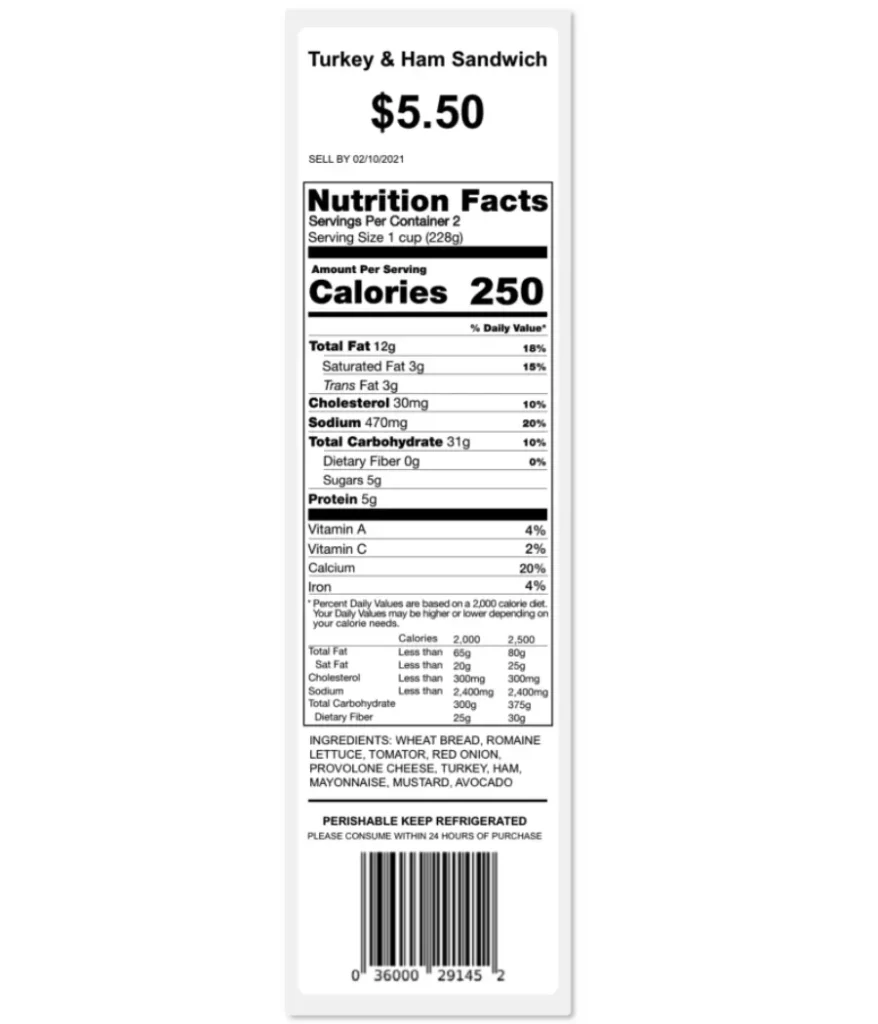

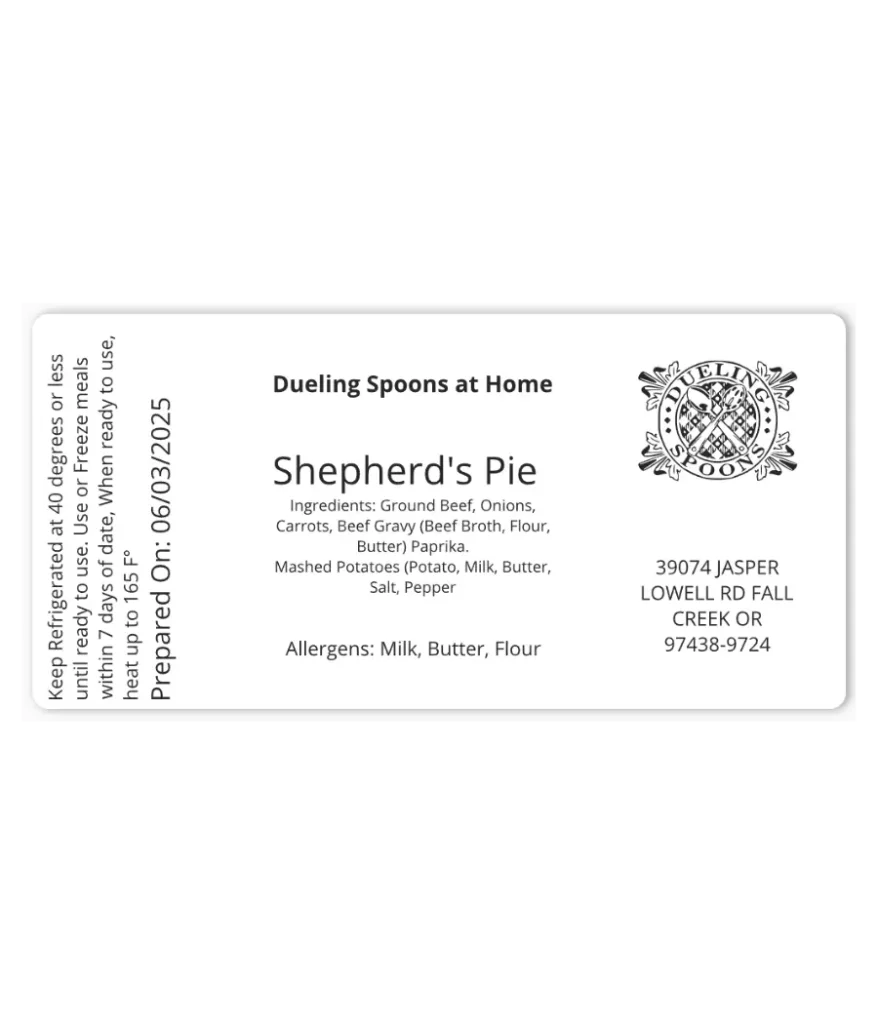

Create or modify easy templates in minutes. Deploy updates across all locations instantly (offline devices sync automatically upon connection). Automatic data syncing ensures correct pricing, FDA-compliant nutrition facts (with proper rounding), ingredients, and barcodes hit the label every time.

The workstation has a user-friendly touchscreen for grocery employees. Employees can manage labels and print jobs not just from dedicated stations but also wirelessly via mobile devices, offering greater flexibility than solely station-based systems. Multi-printer support per station with smart routing automatically sends jobs to the correct printer/label stock, drastically reducing roll swaps and calibration time.

Batch printing optimizes large jobs (perfect for Bakery/Deli). Connect directly with digital scales for accurate variable weight pricing and integrate product data (pricing, nutrition, ingredients) via API to reduce manual entry and errors.

Our printer software minimizes misprints and eliminates “label drift,” saving materials and time.Our printer software minimizes misprints and eliminates “label drift,” saving materials and time.

The workstation has a user-friendly touchscreen for grocery employees. Employees can manage labels and print jobs not just from dedicated stations but also wirelessly via mobile devices, offering greater flexibility than solely station-based systems. Multi-printer support per station with smart routing automatically sends jobs to the correct printer/label stock, drastically reducing roll swaps and calibration time.

Batch printing optimizes large jobs (perfect for Bakery/Deli). Connect directly with digital scales for accurate variable weight pricing and integrate product data (pricing, nutrition, ingredients) via API to reduce manual entry and errors.

Our printer software minimizes misprints and eliminates “label drift,” saving materials and time.Our printer software minimizes misprints and eliminates “label drift,” saving materials and time.

Cloud Based Label Management

No-Code Template Builder

System Wide Syncing

Digital Scale Support

Wireless Printing

Batch Label Printing

Direct Thermal Printing

Thermal Transfer Printing

Label Examples

Digital Task Management: Drive Accountability & Consistency

Jolt’s Task Management solution for grocery stores is designed to replace inefficient paper checklists and digitize operational routines. Grocery managers can easily create, deploy, and manage tasks across all departments and locations. It covers everything from opening/closing procedures, Food Safety protocols, cleaning, and food prep. This allows stores to standardize critical procedures, eliminate outdated paper forms and ensure operational consistency across the board.

Accountability features combat the common issue of “pencil whipping.” Tasks can be configured to require proof of completion, such as a signature, taking a photo, or scanning a QR code. This ensures employees are accountable for performing the task they’re assigned.

Managers get real-time visibility into task completion across departments and stores, allowing for immediate follow-up and ensuring critical control points are consistently monitored.

Jolt integrates checklists with its Information Library, allowing training materials like instructional videos, guides, or recipes to be attached directly to relevant checklist items. This provides employees with on-demand, contextual training exactly when and where they need it, reducing errors, reinforcing correct procedures, and streamlining the onboarding of new staff.

Overall, Jolt’s checklists provide grocery stores with a powerful platform for managing daily operations, ensuring compliance, and driving accountability. Jolt helps grocery retailers improve food safety standards, increase operational efficiency, reduce waste, and maintain consistent brand standards, ultimately contributing to a smoother-running and more profitable operation.

Accountability features combat the common issue of “pencil whipping.” Tasks can be configured to require proof of completion, such as a signature, taking a photo, or scanning a QR code. This ensures employees are accountable for performing the task they’re assigned.

Managers get real-time visibility into task completion across departments and stores, allowing for immediate follow-up and ensuring critical control points are consistently monitored.

Jolt integrates checklists with its Information Library, allowing training materials like instructional videos, guides, or recipes to be attached directly to relevant checklist items. This provides employees with on-demand, contextual training exactly when and where they need it, reducing errors, reinforcing correct procedures, and streamlining the onboarding of new staff.

Overall, Jolt’s checklists provide grocery stores with a powerful platform for managing daily operations, ensuring compliance, and driving accountability. Jolt helps grocery retailers improve food safety standards, increase operational efficiency, reduce waste, and maintain consistent brand standards, ultimately contributing to a smoother-running and more profitable operation.

Digital Checklists and Forms

Photo/QR Code Verification

Automated Notifications

Detailed Completion Reporting

Automated Temperature Monitoring: Protect Inventory & Ensure Food Safety

Jolt uses remote temperature and humidity sensors to monitor fridges and freezers for grocery stores. It uses a long-range, low-power LoRaWAN technology connected via a central Gateway; these sensors offer comprehensive, real-time tracking across the entire store footprint. Jolt offers both ambient sensors for monitoring air temperature and humidity in critical zones like walk-in coolers, freezers, and display cases, and probe sensors for tracking internal product temperatures during processes like cooling or hot-holding. This system ensures precise, 24/7 visibility into environmental conditions vital for food safety and quality.

A major advantage of Jolt’s sensors is the complete automation of temperature and humidity logging, replacing time-consuming and error-prone manual checks. This automated system saves significant labor hours previously spent on manual readings and record-keeping. By eliminating manual entry, it drastically reduces the risk of inaccurate logs, ensuring data integrity. All readings are logged digitally in real-time, creating easily accessible, audit-ready reports that help stores maintain compliance with HACCP principles and regulations set by the FDA, USDA, and local health departments.

Jolt’s system is a crucial safeguard against inventory loss by providing proactive alerts so store management can respond quickly to prevent a crisis. Store operators receive instant notifications via text, email, or in-app push alerts the moment temperatures or humidity levels deviate from pre-set safe ranges. This early warning allows staff to take immediate corrective action by investigating equipment issues or relocating products before spoilage occurs, preventing financial losses. This continuous, 24/7 monitoring provides peace of mind, ensuring valuable inventory is protected around the clock and food safety standards are consistently upheld.

A major advantage of Jolt’s sensors is the complete automation of temperature and humidity logging, replacing time-consuming and error-prone manual checks. This automated system saves significant labor hours previously spent on manual readings and record-keeping. By eliminating manual entry, it drastically reduces the risk of inaccurate logs, ensuring data integrity. All readings are logged digitally in real-time, creating easily accessible, audit-ready reports that help stores maintain compliance with HACCP principles and regulations set by the FDA, USDA, and local health departments.

Jolt’s system is a crucial safeguard against inventory loss by providing proactive alerts so store management can respond quickly to prevent a crisis. Store operators receive instant notifications via text, email, or in-app push alerts the moment temperatures or humidity levels deviate from pre-set safe ranges. This early warning allows staff to take immediate corrective action by investigating equipment issues or relocating products before spoilage occurs, preventing financial losses. This continuous, 24/7 monitoring provides peace of mind, ensuring valuable inventory is protected around the clock and food safety standards are consistently upheld.

Wireless LaRa Senors & Gateway

Real-Time Temperature Tracking

Customizable Alerts